Rock guard wear and track life

- Interior Undercarriage

- Dec 30, 2019

- 1 min read

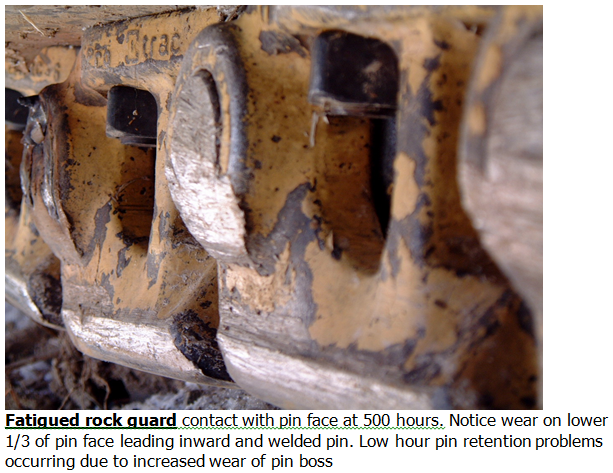

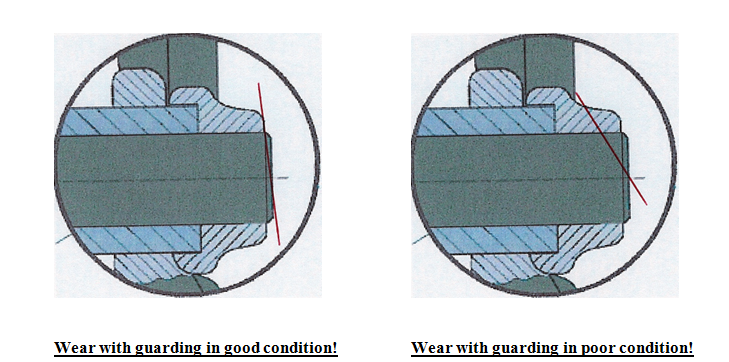

Rock guarding systems serve to play the roll of keeping the rail inside the flanges of the lower track rollers. When new, they are square right to the bottom of the rock guard which makes nice even contact of the pin boss on the rail. As they age, the lower portion of the guard gets worn away and needs to be replaced.

If the guards are not replaced and a new undercarriage is installed, only a very small portion of the guard makes contact with the pin boss instead of a nice even square contact. This acts like a file against the side of the pin boss closest to the strap or "Ride Surface" of the rail.

Since link material is softer than pin material, the hard steel of the rock guards will eat through the link and pin boss (which is what retains the pin in place) it will then start to walk the pins out, as well cause all sorts of other issues.

Rock guards serve a very critical role in the life of an undercarriage and need to be looked at and replaced with every set of undercarriage for maximum life span. If neglected they will accelerate wear on the rail in a way they are not designed to be worn.

Comments